View the videos from presenters at the 4th Annual Safety in Spine Surgery Summit. Learn insights and practical techniques for improvement of safety in spine surgery from experts in the medical field as well as other fields.

We are excited to be convening the 4th Annual Safety in Spine Surgery Summit on April 26, 2019 in New York City, NY! In addition to the fantastic roster of speakers, we look forward to sharing the following:

- Latest in Best Practices for Safety in Spine Surgery

- Using tools to reduce variability and improve predictability of achieving positive outcomes

- Discussing the importance of safety on the macroeconomic level

- Designing Talent, culture and team to achieve best outcomes

- Protecting surgeons and providers

- Discussing value-based care in spine with all stakeholders

We look forward to seeing you at the Safety in Spine Surgery Summit!

The Safety in Spine Surgery project was thrilled to have hosted the 3rd Annual Safety in Spine Surgery Summit on Friday, April 20, 2018 at NewYork-Presbyterian Hospital. The event brought together a diverse audience of spine surgeons, OR directors and hospital executives from across the nation to network and learn about the numerous safety and quality advances that are being made in the field.

This year’s theme was “Toward New Rules of Engagement for an Increasingly Complex Spine World.” Dr. Michael Vitale (pictured in photo, right), chaired the event and was joined by the event’s co-chair Dr. Lawrence Lenke (pictured in photo, left).

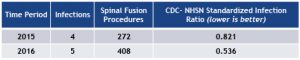

Without doubt, the impact of complications like surgical site infection (SSI) can have a tremendous burden on patients, their families, surgeons, hospitals, and society as a whole. As with most complications in healthcare, SSI should be thought of as the result of a combination of host, technique, systems and culture challenges. When multiple defects accumulate, SSI overwhelms the various countermeasures and a clinical infection ensures.

When the defects all align, it allows for these factors to allow passage through the “Swiss cheese” of host, perioperative, and systems defenses. Our role in making care better extends far beyond the time in the operating room. Our highest performance can only come from the ability to develop a high functioning team with unique and synergistic inputs across the entire care continuum, starting well ahead of surgery to include culture and involvement of multiple stakeholders all working towards a shared goal with everyone understanding the importance of the role they play. The greatest opportunity to improve quality, safety, and value lies in the period before the skin incision and long after it is closed. Increasingly, it’s not just the surgeon’s role in acting as the captain of the ship but understanding the importance of “slowing the machine” to consider the full spectrum and extent of potential surgical risk and working with the team to attempt to optimize preoperative care and potentially alter the characteristics of the surgical approach for a given patient.

Work at S3P is dedicated to exploring the role of the multidisciplinary team in minimizing the possibility of complications after spine surgery. Interventions and risks are being explored as efforts to affect the host, surgical technique, culture and systems of care. As with all quality improvement efforts, these must adapt over time to create sustained and iterative improvements in care. Our team began this journey several years ago and we look forward to involving you in this as well.

How Lessons from Cycling Can Inform Efforts at Continuous Improvement

A recent conversation with an avid cycler helped me draw interesting parallels between how sport and the pursuit of skill so often intersects with our mission to make care better in healthcare. Britain’s national efforts in cycling provide such an interesting case study, taking a program who had never won a single gold medal in its 76 year history to winning seven out of 10 gold medals in two consecutive Olympics and applying the same discipline to lead one of the most successful professional cycling teams ever.

Sir Dave Brailsford, the coach responsible for these efforts, took the principles of the Toyota Production System, also called lean, to infuse the team with the spirit of Kaizen, or continuous improvement. He thought that if the team broke down everything they could think of that went into competing better on a bike, and then improved each element by 1%, then these marginal gains could achieve a significant aggregated increase in performance. This came from everything to the traditional areas of experimenting in wind tunnels for aerodynamic, to applying 5S techniques to the mechanics team truck and painting the floor white to prevent slips from grease, to teaching athletes about proper hand hygiene from a surgeon. This even went as far as requiring all athletes to sleep on team provided mattresses and pillows so athletes could sleep in the same posture with the same support every night. Taken together, they felt that it gave a competitive advantage.

These principles of looking at strategy, human performance, and continuous improvement have the same applications to how surgery is performed. For strategy, so much cognitive effort needs to be spent on understanding patient’s unique attributes, understanding plans for surgery, and involving the team. This can also involve slowing down the machine and working with a multidisciplinary team to understand the approach. With S3P efforts, this include recommending using multidisciplinary indications conferences with anesthesia, medicine, and nursing to fully discuss a patient’s treatment plans.

For human performance, this truly involves a surgeon treating themselves as athletes, caring for their physical conditions and optimizing their movements. But this also involves attention to behavioral psychology and creating an environment for optimum performance. This may involve routines the evening and morning before surgery to cognitively rehearse the procedures but also can include preventing heuristic biases from affecting decision making. At S3P, this involves the development of formal risk stratification scores to formalize the requirements and opportunities for “slowing the machine” and optimizing patients’ modifiable risk factors.

The final aspect of continuous improvement plays heavily into Sir Dave’s efforts at finding marginal gains. The same principles are applied within my own OR. For the past year, we have been using the comprehensive unit-based safety program to work with my operative team to fully map out the steps involved in preparing a patient for surgery to incision. From there, we brainstormed ways to drive more efficiencies. Things included marking with tape the position of the table and posting laminated photos of the way the lights should be set up. While each step would only save several minutes at most, as we found more and more opportunities for efficiencies, this began to increase our time to set up by up to 20%. Today, we are applying this across the entire continuum.

Identifying these principles as critical success factors and ensuring they are in place can allow everyone to focus on improvements and reach an optimal place to improve quality, safety, value, throughput and efficiency.

.png)

.png)